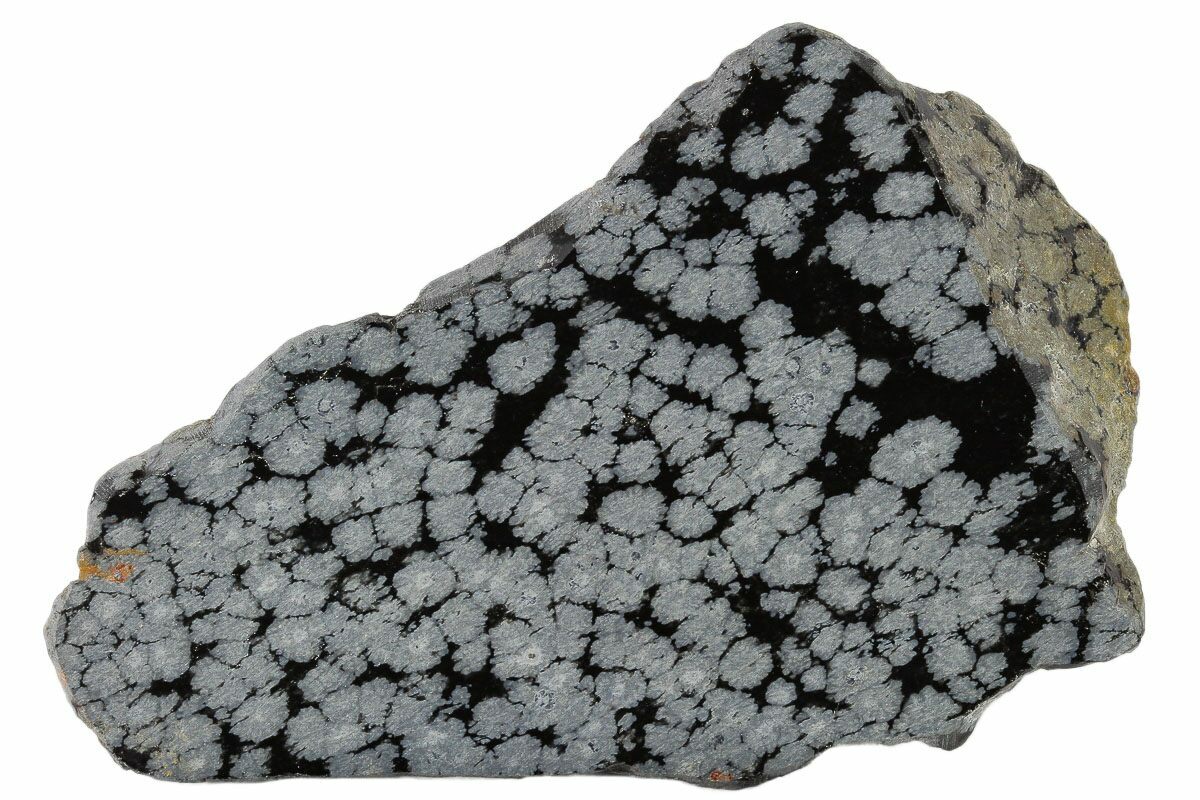

A carnelian agate after first 3 steps. The fourth step, polishing, is technically the final step in the process, the one that shines your beautiful stones. When cut and polished, these specimens are referred to as 'snowflake obsidian' (see photos). Rarely, obsidian has an iridescent or metallic 'sheen' caused by light reflecting from minute inclusions of mineral crystals, rock debris, or gas. Scott polishes a piece of rainbow obsidian and shares some of his tips for a good shine. This is our first-ever video! We thought we were just experimenting, but we ended up with something that others may find entertaining and educational.

Traitement..The gemstone Obsidian is a natural glass formed from volcanic activity in the same way as Granite. Hitman 2 silent assassin full movie download. Obsidian is 35-80% Silica and is low in water content. It has been used in tool-making and jewelry-making for centuries . Its sources are the Caucasus Mountains, Georgia, Armenia and Russia.

Below are images showing rough snowflake Obsidian being cut and polished into beautiful gemstones.

How to Select Obsidian Rough

It is best to choose a piece of Obsidian rough with the least amount of cracks and visible lines. Sometimes Obsidian may crack whilst cutting along cracks. We selected a large piece to start with and cut it in half.

The best saw to use to cut or slice Obsidian is a Diamond Saw. Obsidian is easy to saw and makes the ideal stone to cut and polish. Always wear a protective mask when working with Obsidian Rough as the silica can be harmful to your health.

Always have plenty of water running over the saw blade orpolishing wheel as Obsidian, this will minimise the amount of silica dust rising into the air and being inhaled.

We used a 6 inch saw blade with 0.18 grit and 3 polishing wheels which were Diamond impregnated from 180,240 to 400 grit, then a final polish.

Obsidian is also fun to carve. Use a Dremel drill with diamondtip drill bits. They are the best and then polish with final laps or on pig skin or polish clothes.

SHOP FOR LAPIDARY SUPPLIES

The gemstone Obsidian is a natural glass formed from volcanic activity in the same way as Granite. Obsidian is 35-80% Silica and is low in water content. It has been used in tool-making and jewelry-making for centuries . Its sources are the Caucasus Mountains, Georgia, Armenia and Russia.

Below are images showing rough snowflake Obsidian being cut and polished into beautiful gemstones.

How to Select Obsidian Rough

It is best to choose a piece of Obsidian rough with the least amount of cracks and visible lines. Sometimes Obsidian may crack whilst cutting along cracks. We selected a large piece to start with and cut it in half.

The best saw to use to cut or slice Obsidian is a Diamond Saw. Obsidian is easy to saw and makes the ideal stone to cut and polish. Always wear a protective mask when working with Obsidian Rough as the silica can be harmful to your health.

Wincleaner Memory Optimizer is yet another Auto Optimization process supporting free memory optimizer software. Your PC’s memory can be optimized automatically as well as manually with this freeware. The Auto Optimization feature of this free memory optimizer requires a RAM usage level, which you can adjust by its respective slider bar (up to 160 MB). Scroll down to 'System Tools' and click 'Disk Defragmenter.' Select your hard drive from the list (if Windows has not automatically done so), then click 'Defragment' to begin the process. Defragmenting removes the incomplete and corrupt files that tend to scatter. Free up ram memory. Type free up disk space in the Search box. Tap or select Settings. Tap or select Free up disk space by deleting unnecessary files on the left side of your screen.

Always have plenty of water running over the saw blade orpolishing wheel as Obsidian, this will minimise the amount of silica dust rising into the air and being inhaled.

We used a 6 inch saw blade with 0.18 grit and 3 polishing wheels which were Diamond impregnated from 180,240 to 400 grit, then a final polish.

Obsidian is also fun to carve. Use a Dremel drill with diamondtip drill bits. Transferring music from macbook to iphone. They are the best and then polish with final laps or on pig skin or polish clothes.

SHOP FOR LAPIDARY SUPPLIES

Ce texte a été traduit automatiquement. Afficher l'original?Black, Lustrous, Beautiful

Obsidian and Apache Tears make awesome tumbled stones. When tumbled properly they are jet black, highly lustrous and beautiful. Many of them are also transparent. However, some people have a hard time tumbling these natural glasses because they often bruise or chip in the tumbler. However, you can easily get super results by tumbling them gently in a generous amount of reusable ceramic media. We describe the process and a few tips that will help ensure your success.

Tip #1: These materials are soft. They have a Mohs hardness of about 5. Because they are soft, they shape quickly in a tumbler barrel with silicon carbide grit. We skip the coarse grit step and use a three step tumbling process - 1) medium grit; 2) fine grit; and, 3) polish.

Tip #2: These materials are fragile. The particle-to-particle impacts within the tumbler are what cause bruising and chipping. When we tumble them we always surround them with small cylinder-shaped ceramic media. We fill the tumbler barrel with about 50% ceramic media and about 50% obsidian/Apache tears. The ceramic cylinders act like roller bearings and promote a smooth tumbling action. They prevent the pieces of natural glass from hammering against one another in both rotary and vibratory tumblers. Without the cylinders, the pieces of glass will likely be cracked, broken or chipped around the edges.

Tip #3: These materials can produce gas in the tumbler barrel. You read that right. Small amounts of gas are produced as these materials are worn away in the tumbler. This only causes a problem when your tumbler barrel has a lid that can be pushed off by a small amount of gas pressure in the barrel. If you have a vibratory tumbler this is not a problem. Take care of the gas by 'burping your barrel' if it starts to bloat. Or, you can follow the advice given by Steve Hart, author of the book 'Modern Rock Tumbling' - he adds 1/2 teaspoon of baking soda to the tumbler barrel to prevent gas production. If you want more information on this read our article: Gas in the Rock Tumbler Barrel?

Tumbling Recipe: Apache Tears or Obsidian in a ROTARY Tumbler

Barrel Loading: Fill the barrel 2/3 full with 50% Apache Tears and 50% small ceramics.

Step 1: Two tablespoons medium grit (150/220) per pound of rock and ceramics, enough water to cover the rocks. For tumbling whole Apache tears, run four or five days. For broken pieces of obsidian tumble for seven days and inspect. Tumble longer if needed.

Step 2: Two Tablespoons of fine grit (500 or 600) per pound of rock and ceramics, enough water to cover the rocks, tumble for four or five days.

Step 3: Two tablespoons of TXP or #61 Rapid Polish per pound of rock and ceramic, enough water to cover the rocks, tumble for seven days.

Burnish in soapy water for 30 minutes - only if needed. Learn more about burnishing here.

Tumbling Recipe: Apache Tears or Obsidian - VIBRATORY Tumbler

Barrel Loading: Fill the barrel to manufacturers suggested level with 50% Apache Tears and 50% small ceramics.

Step 1: One-half tablespoon of medium grit (150/220) per pound of rock and ceramics, add just enough water to make the grit stick to the rock and media. Run for two days, inspecting frequently to maintain a thin mud slurry. Rinse and inspect your rough after two days. If more time is needed, run for two additional days. Continue until you are satisfied with the shape.

Step 2: One-half tablespoon of fine grit (500 or 600) per pound of rock, add just enough water to make the grit stick to the rock and media, tumble for two days.

Polishing Obsidian

Step 3: One-half tablespoon of TXP or #61 Rapid Polish per pound of rocks, add just enough water to make a thin polish slurry, tumble for two days. Tumble longer if needed. Don't over tumble.

Burnish in soapy water for 30 minutes - only if needed. Learn more about burnishing here.

Happy Tumbling!

RockTumbler.com Authors

Polishing Obsidian In A Rock Tumbler

Polishing Obsidian With Dremel

| Hobart M. King has decades of rock tumbling experience and writes most of the articles on RockTumbler.com. He has a PhD in geology and is a GIA graduate gemologist. He also writes the articles about rocks, minerals and gems on Geology.com. |